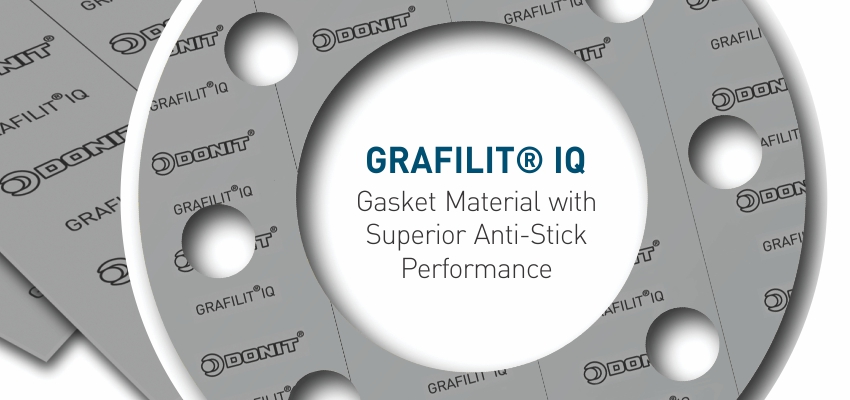

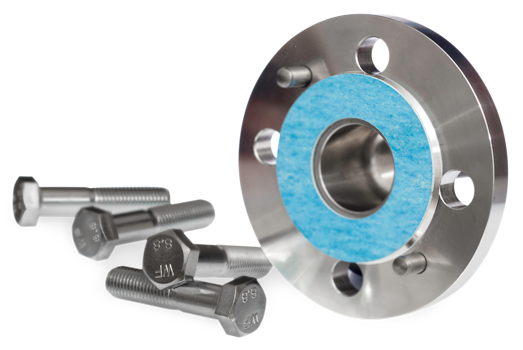

Choose Our Safety First Sealing Solutions

Our fiber sheets and gaskets are made from non-asbestos (CSF/CNAF), expanded graphite, aramid/graphite, PTFE, mica or rubber sealing materials. They are used in all industries in a variety of applications from -250°C to 300°C.

Regular maintenance is essential if you wish to delay the deterioration and extend the service life of any equipment or machine used in the process. Our prevention solutions include the widest range of state of the art technology used in the industry.

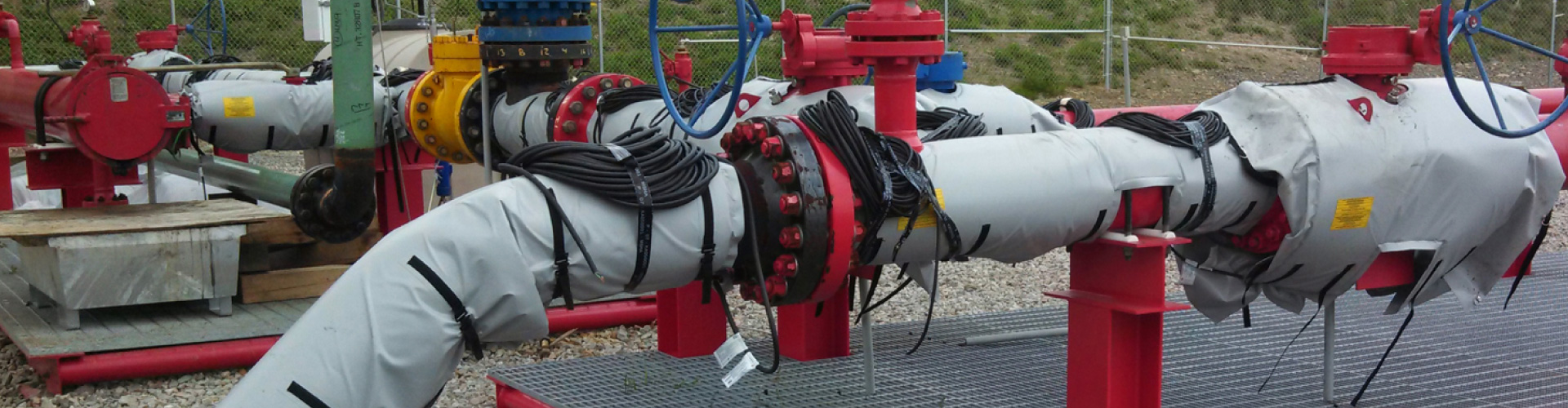

There is a significant potential for energy savings by improving thermal insulation on industrial process pipelines, valves, pumps and heat exchangers. By implementing regular surface thermal imaging audits, it is easy to identify the areas of improvement.

Explore Our 'Save Money & Nature' Insulating Solutions

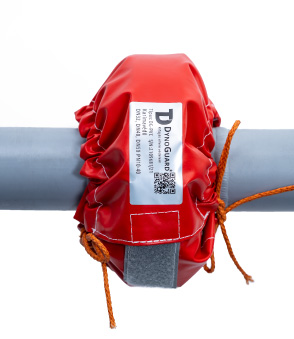

Industrial insulation in the various points of a production line subject to heat or cold dispersion, obtain a considerable reduction of energy consumption and significantly reduce greenhouse gas emissions into the environment. DYNOTEQ thermal insulation jackets support to overcome rising electricity and gas prices and achieve greater environmental sustainability. The payback period for heating installations without other subsidies is 1-2 years, and for steam systems within 1 year!

European Industrial Insulation Foundation (EiiF) study showed that about 10% of the surfaces to be insulated in Europe have poor quality and decades old insulation dating back to the era of the region’s industrial boom. Properly insulating these surfaces, nearly 9.5 million GJ energy could be saved in Hungary alone. In a DN100 valve with a surface area of 0,38m in a globe valve at 240°C operating temperatures more than 2.200€ can be saved a proper insulation.

Facility managers no longer see sustainability as a tick-box or checklist exercise. It is a critical investment area where organizations can realize genuine returns and opportunities for competitive advantage. All hot (50-1000°C) surfaces found in industry can be insulated with DynoFlex insulation blankets designed for the conditions. It is best to start an insulation project on surfaces that could not be insulated with other competing solutions. In a centrifugal pump the cost is ca. 139€ of the insulation; however the annual saving is more than 1.800€; so a ROI of less than a month.

Using DYNOTEQ solutions at critical points in a valve / pipe system will assure immediate results considering energetics, EHS, maintenance and expenditure. You will see reduction of CO2 emissions, experience safety at surface contact protection, accessibility to the system can be ensured by dismantling in 1 minute (and ca. 1 minute reinstallation) as well as fastest possible break-even point due to reduced energy consumption and buying fewer CO2 quotas.

Using special measuring equipment and advanced thermographic cameras we list all uninsulated valves and surfaces. Following onsite discovery, we calculate ROI based on ASTM C 1129-12 and C680 standards, define heat savings in both nature and company resources and present our offer. We deliver, execute and install all custom-made insulations with 18 months 'Exact Fit' warranty. Installation process is always followed by thermographic audit for documenting all cold side (touching) temperatures and investment payback time double checking.

Start Your Next Project With Us

Everything we do, centers around you - our customers. We understand every project is unique and needs to result in a customised solution that best fits

these needs.

Focusing on your business we are securing our success. To maintain competitiveness we strive to improve our manufacturing processes constantly investing in latest technology.

We personally stand behind every project we undertake, realising it's not just product, service and logistics quality what we are after. It's satisfaction of job well done what s driving us.

Latest News And Videos From Dynoteq

Lorem ipsum

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Lorem ipsum 2

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Lorem ipsum 3

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Lorem ipsum 4

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

What Makes us The Preferred Sealing Partner

Dynoteq high quality and environmentally friendly sealing solutions can fulfill different needs and are suitable for various industries and even the most challenging applications. Being in business for so long we know there will always be some unexpected urgent sealing problems to be solved and that is when our broad product portfolio comes in to the rescue. These acts are in need of fast, in-place, easy repairing technologies that can help not only to operate the system until the next scheduled maintenance but to prevent production down-time.

World-class Engineered Sealing Solutions

size DN 15-1200

EXCELLENCE IN INSULATION JACKETS

Dynoteq insulation jackets are smart solutions for preventing heat losses around the valves at hot or cold liquid transporting pipelines.

Benefits:

» minimize heat loss for energy efficiency

» keep desired temperature of flowing contents

» prevent valves from freezing up & overheating

Dynoteq expert say:

"To reduce leakage risks, pump users should carefully consider the characteristics of their equipment to ensure effective sealing and reduce leakage incidents."

Peter Kowalsky, R&D manager